The Two Types of Commercial Foam

Open cell foam (also known as reticulated foam) has a high degree of porosity, that allows for the interconnection of all of the pores within the foam. This high degree of porosity in turn creates a high degree of permeability, which allows fluids to flow in and out of the foam structure.

In order to meet exacting specifications, we must be able to manipulate the level of porosity in our foams. Microporous foam (<2nm) to macroporous foam (>50nm) are manufactured at both of our facilities in Cookeville, TN and Utica, NY. Having the knowledge, experience and facilities needed to be able to manipulate porosity of the foams we manufacture allows us to control the viscosity of the liquids and the amount of liquid applied to surfaces/substrates during the application process.

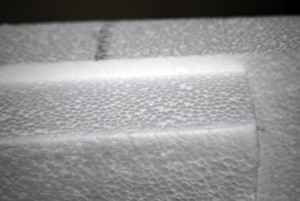

Closed Cell Foam

Closed cell foam does not have a network of interconnected pores, and thus does not have a high degree of porosity or permeability. Closed cell foam is also generally harder, costs more to produce and has a higher overall compressive strength.

This lack of porosity and permeability creates foam in which there are solid “walls” that encapsulate liquids, preventing the addition or removal of subsequent liquids. A prime example of this is the expanded polystyrene (EPS) foam used in a standard coffee cup. This type of foam is excellent at containing liquids, such as coffee, but not at releasing liquids for printing applications.

Foam Applications

The following chart details the unique attributes of both open and closed cell foam that make them more suited to certain applications.

| Open Cell Foam | Closed Cell Foam |

| When holding a liquid you are able to add or remove additional liquid as needed | Completely encloses anything that the foam is holding, preventing the addition or removal of the substance being held |

| When dispensing things the porosity of open cell foam can be manipulated to control the rate at which dispersion happens | Because closed cell foam encapsulates things, it does not allow items to be dispensed without destroying the original foam structure |

| Open cell foam is a great option for metering things, by carefully altering the number and size of the pores within the foam structure we can control how an item is metered | Closed cell foam is not well suited to metering things and is primarily used to insulate items from either the elements or blunt force shock. |

Contact us to find out what type of foam is best for your engineering and printing needs.