Industrial Oil Containment and Clean Up

Work place oil and gasoline spills are a common problem facing many industries, both domestically and abroad. According to a 2009 study by the American Petroleum Institute, between 1998-2007 there were over 77,000 barrels of oil spilled in conjunction with the storage and use of oil or gasoline in the USA alone. Each one of these 77,000 spills required significant time, money and man hours to clean up and dispose of the spill in accordance with state and federal regulations.

Absorption Foams

That is where absorption foams come in handy. Absorption foams offer several advantages over other petroleum-based clean-up tools, making them ideally suited for use in industrial and/or manufacturing settings. Absorption foams are equally adept in the cleaning and removal of non-petroleum oils, including plant-based oils.

Highly absorbent: absorption foams by nature are engineered to be highly absorbent, with the capability of absorbing over 90% of spilled oil/gasoline in a relatively short period of time. This makes absorption foams ideally suited to clean up mechanical spills, as they provide the quickest clean up time and thus the quickest return to use for a piece of machinery. Saturated absorbent foams can be collected with a dustpan and broom, leaving the floor surface dry.

Fluid retention: absorption foams actually retain the oil/gasoline with which they come in contact and allow other liquids, such as water, to easily pass through. The rate of absorption and the amount of fluid retention can be engineered to exact specifications by manipulating the properties of the foam. The ability to specifically engineer the absorption foam not only makes the clean up and disposal process easier, it allows for the transportation and reclamation of the spilled material, if needed.

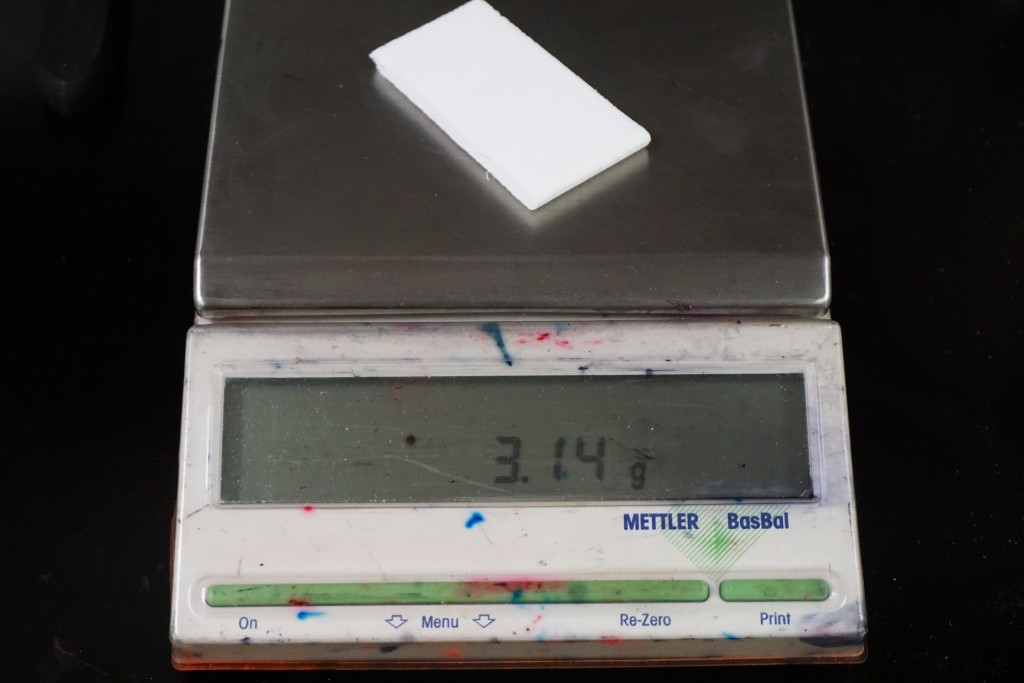

Ease of use: absorption foams are simple to use, require little training and can be designed to meet the precise needs of individual situations. The fact that absorption foams can be manufactured to exacting specifications means the foams can be molded to fit a specialized piece of machinery. They are light weight, easy to handle and easy transport. These attributes allow absorption foams to be used by anyone, regardless of size or strength, making them the best option for the job site.

Porelon foam is light weight and easy to transport.

Absorption foams are the quickest, most efficient, and most cost-effective method of dealing with work place oil/gasoline spills. If you would like learn more about how custom-engineered absorption foam can benefit your organization, and keep you compliant with state and federal regulations, contact us today.